Contract Businesses

We are capable of handling contract services from the design to

production of pharmaceuticals.

Do you have any problems designing or manufacturing ointments, creams, lotions or solutions?

Based on our research on external skin preparations and technologies regarding various dosage forms accumulated over many years,

we confidently provide pharmaceuticals from their design to production.

In particular, emulsified creams and lotions require a variety of base formulations depending on the main ingredients.

Because base materials tend to easily separate, we have established stabilization technology through research on emulsified formulations over many years.

We are capable of handling orders from high-mix low-volume production to mass production.

We also comply with investigational drug GMP.

You can also consult us when you are only examining prescriptions or for non-production problems.

Formulation technology

Technological development power

| Active ingredient | Product | Manufacturing company | Ointment | Cream | Lotion |

|---|---|---|---|---|---|

| Difluprednate | Difluprednate 0.05% "IWAKI" | IWAKI SEIYAKU CO., LTD. | ○ | ○ | ○ |

| Brand product | ○ | ○ | |||

| Clobetasone Butyrate | Clobetasone Butyrate 0.05% "IWAKI" | IWAKI SEIYAKU CO., LTD. | ○ | ○ | ○ |

| Brand product | ○ | ||||

| Dexamethasone | Dexamethasone 0.1% "IWAKI" | IWAKI SEIYAKU CO., LTD. | ○ | ○ | ○ |

| Brand product | ○ |

Formulation technology

| Dermatological drugs | Dosage form | Technology | Remarks |

|---|---|---|---|

| Ointment | Dispersion | Various dispersion methods will be selected based on the stabilit and efficacy (skin permeability) of ingredients. | |

| Texture | Varies significantly by viscosity and spread. The optimal sense of use can be performed. | ||

| Cream Lotion Solution |

O/W type, W/O type base |

Creams are available in both types. | |

| Base stability | We established technology to select stable bases based on our long-term research on emulsifying agents. | ||

| Dispersion | Like for ointments, various dispersion methods will be selected based on stability and efficacy (skin permeability) of ingredients. | ||

| Texture | Varies significantly by viscosity and spread. We aim to realize the optimal sense of use. |

History of contract services

| Ointments | Manufacturing methods and IND Production |

|---|---|

| Lotions | Manufacturing methods and IND Production |

| Examination for drug product formulation of creams containing new excipients |

Pharmaceutical formulation designs, standard test methods, stability tests |

|---|---|

| Examination for formulation of combined lotions (four active ingredients) | Standard test methods, stability tests, comercial scale production |

| Examination for formulation of combined ointments and creams (four active ingredients) | Standard test methods, stability tests, comercial scale production |

|---|

History of contract services

Iwaki Seiyaku has accumulated research on dermatological drugs and technologies related to various dosage forms over many years. We select the optimal base and manufacturing method in consideration of the characteristics, etc., of the ingredients.

We design pharmaceuticals in consideration of all possible concerns, including physical stability,

appearance, sense of use, and efficacy of pharmaceutical products, as well as the chemical stability of the active ingredients.

Please feel free to contact us for production and research related to dermatological drugs.

Available dosage forms

Dermatological drugs

Pharmaceutical formulation designs

Ointment (dissolution, dispersion)

Cream (O/W, W/O)

Lotion (O/W, W/O)

external solution

Investigational new drugs

Ointment (dissolution, dispersion)

Cream (O/W, W/O)

Lotion (O/W, W/O)

external solution

Commercial scale production

Ointment (dissolution, dispersion)

Cream (O/W, W/O)

Lotion (O/W, W/O)

external solution

Test and Assessment

- Stability test (measurement: Temperature: -80°C to 60°C, light, humidity)

- Preservative-effectiveness test

- Viable count test

- Absorption performance test (permeability, release)

- Physical properties evaluation (viscosity, spreadability, consistency, speculum)

Introduction to our facilities

Kamata Plant

Main facilities

Lotion filling machine

Cutting-edge filling machine for PTP packaging of tablets

| Solid preparations | Process | Facilities |

|---|---|---|

| Granulation | Mixing and granulating machine | |

| Granulate-refining | Crushing-type sizer | |

| Drying | Chamber dryer | |

| Mixing | V-shape mixer | |

| Tableting | Tableting machine | |

| Film coating | Vented tablet coating machine | |

| Inspection | Tablet checker | |

| Filling and packaging | Powder filling line | |

| PTP filling and pillow-type packaging line | ||

| Solutions and semi-solid preparations |

Preparation | Dissolution tank |

| Storage tank | ||

| Vacuum emulsifier | ||

| Filling and packaging | Lotion filling machine | |

| Tube filling line | ||

| Tack labeling machine | ||

| Cartoning line | ||

| Shrink-packaging line |

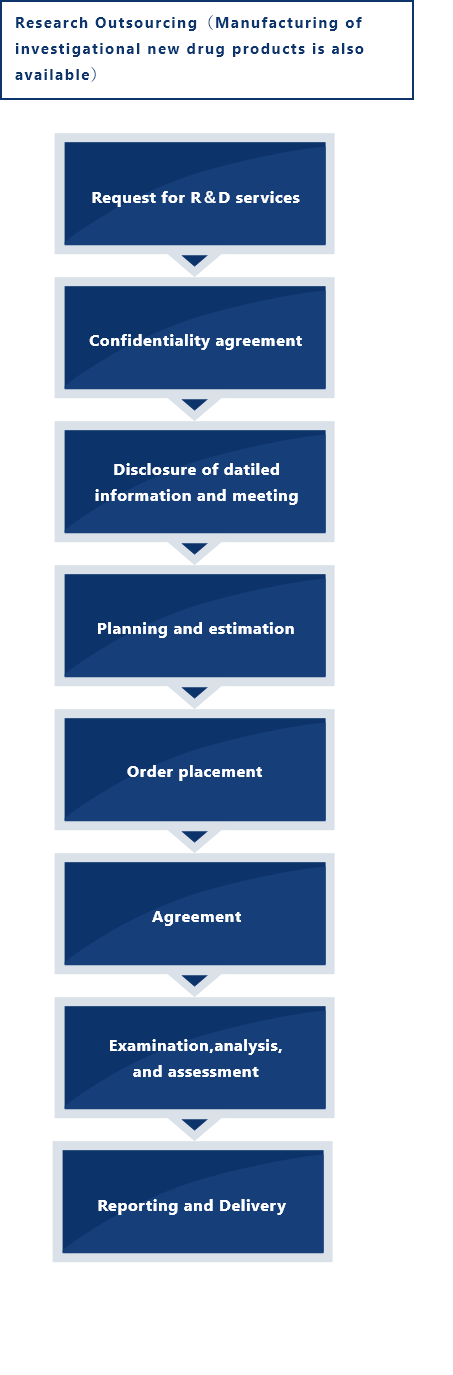

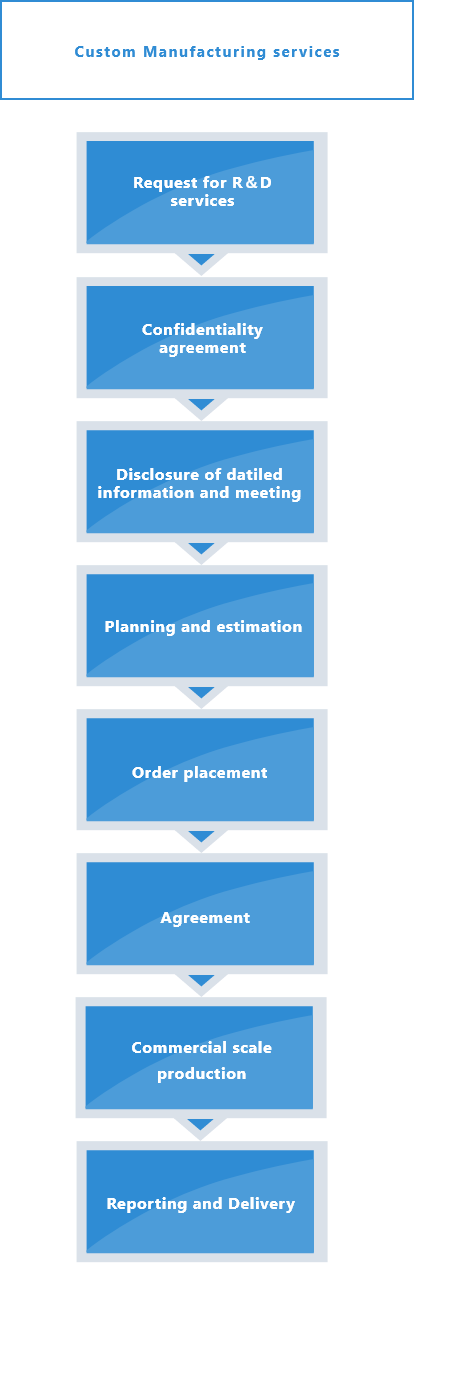

Flow of Custom Manufacturing Services